|

1 2 3 4 5 6 7 8 9 10 11

Winding

Hot pressing

Wrap core

Spraying gold

Welding irrigation (group)

Curing baking

Sorting

Sorting

Cutting foot

Packaging

|

Winding Winding core, strict control of temperature and humidity (humidity less than 25%), wrapped core sealed in a plastic bag, transfer to the drying room for use. |

Hot pressing Hot pressing, vacuum hot pressing machine, temperature control at 105 degrees, pressure according to the film thickness, the principle should not damage the metal film coating (coating transfer), strength control in 4kg-10kg; |

Wrap core Wrap core, speed up flow speed, no impact deformation. |

Spraying gold before spraying gold on the core of safety capacitor, the wrapped core is sent to the vacuum oven again to bake at 50℃ to remove moisture, and then the first and second spraying of four-element alloy; The third and fourth sprays were 30:70 tin-zinc alloy with a thickness of 0.3-0.35mm. Wrap core, speed up flow speed, no impact deformation. |

Welding irrigation (group) first of all, the use of air conditioning to control the temperature and humidity of the workshop, to prevent sealing glue moisture absorption; Second group operation, enabling (according to the voltage resistance 2500V for enabling) - welding (the first test 20 short circuit discharge 200 times, capacity OK, leakage current OK, then the operation) - glue (glue) - shell - second filling sealant (pay attention to the glue wire drawing and climbing caused by the bad conjoined safety capacitor) |

Curing baking use negative pressure vacuum oven, 85 degrees for half an hour, 105 degrees for 2 hours. Regularly clean the potting grease inside the oven to prevent fouling of the capacitor body. |

Sorting Sorting: high frequency test, eliminate bad welding, 10 short circuit charge and discharge test, voltage adjustment for 2500V DC test |

Sorting Sorting: high frequency test, eliminate bad welding, 10 short circuit charge and discharge test, voltage adjustment for 2500V DC test |

Cutting foot Cutting foot: the CP line length of conventional production is 23MM. If the CP line length required by the customer is 3.5mm or 4MM, part of the length should be cut off. |

Packaging Packaging: according to the size of the product packaging, pay attention to short packing! |

|

|

1 2 3 4 5 6 7

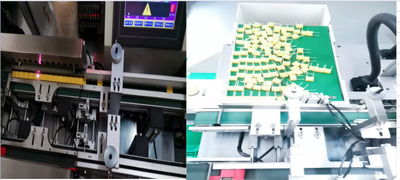

capacitor core reeling machine

capacitor core reeling machine

Braiding process

Sorting test workshop

|

capacitor core reeling machine This winding machine is dedicated to the medium and small metallized film capacitor automatic winding machine, suitable for polyester, polycarbonate, polypropylene and other winding materials, the film thickness of the minimum of 2μm, in a pair of mandrel can be wound at the same time a single or double capacitor core, winding core diameter range :2,5 ~ 18mm. Core-winding shaft diameter :2,2.5,3,4,5,6, 6, can be used interchangeably. Can be single or double winding. Minimum thickness of winding film :2μm |

capacitor core reeling machine This is the first step in the production process, which involves winding the film material through the medium to form the core of the capacitor. Neat, uncluttered work space. |

Braiding process Mainly used for epoxy coating products |

Sorting test workshop Through the main performance of the product to test, sorted out 100% qualified products |

|

|

|

Contact Person: Miss. Lei

Tel: 18929192705